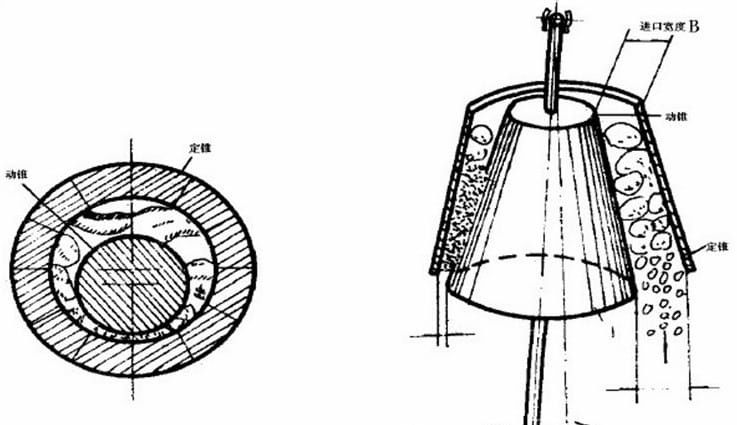

Differences between medium and fine crushing cone crushers and gyratory crushers

The specifications of medium and fine crushing spring cone crushers are expressed by the bottom diameter D of the movable cone. The working principle of medium and fine crushing cone crushers is basically similar to that of gyratory crushers, but there are still differences in structure. The main differences are:

(1) The two cones of the gyratory crusher are both steeply inclined. The movable cone is an upright truncated cone, and the fixed cone is an inverted truncated cone. This is mainly to increase the feed opening. The two cones of the medium and fine crushing cone crushers are both gently inclined upright truncated cones, and there is a certain length of parallel crushing area (parallel belt) between the two cones. This is to control the product particle size. Because the design of medium and fine crushing crushers takes the quality of crushed products and production capacity as the primary factors.

(2) The movable cone of the gyratory crusher is suspended on the crossbeam on the upper part of the machine, and the movable cone of the medium and fine crushing cone crusher is supported on the spherical bearing at the bottom.

(3) The gyratory crusher adopts a dry dust prevention device, while the medium and fine crushing cone crushers adopt a water seal dust prevention device.

Schematic diagram of cone crusher operation

(4) The gyratory crusher uses the rise or fall of the movable cone to adjust the size of the discharge port, while the medium and fine crushing cone crushers adjust the height position of the fixed cone (adjusting ring) to adjust the width of the discharge port. According to the different discharge port adjustment devices and safety devices, the medium and fine crushing cone crushers are divided into spring type and hydraulic type cone crushers. The working mechanism of the spring type cone crusher consists of a movable cone with a manganese steel liner and a fixed cone. The movable cone is pressed onto the main shaft 15, and one end of the main shaft is inserted into the conical hole of the eccentric sleeve. When the eccentric sleeve rotates, it drives the movable cone to perform a swiveling motion. In order to ensure the requirement of the movable cone to perform a swiveling motion, the lower surface of the movable cone should be made into a spherical surface and supported on a spherical bearing. The entire mass of the movable cone and the main shaft is borne by the spherical bearing and the frame. The safety device of this machine is the spring installed around the frame. When non-crushed materials such as large iron blocks enter the crushing chamber, the support ring and adjustment ring supported on the spring are forced to lift up and compress the spring, thereby increasing the distance between the movable cone and the fixed cone, increasing the discharge port, discharging non-crushed materials, and avoiding damage to the machine parts. Then, under the elastic force of the spring, the support ring and adjustment ring quickly return to their original position and resume crushing.

Hydraulic Cone Crusher

Medium and fine crushing cone crushers are divided into three types according to the form of the crushing chamber: standard type (for medium crushing), intermediate type (for medium and fine crushing) and short head type (for fine crushing). Among them, the standard type and short head type are more widely used. Their main difference lies in the cross-sectional shape of the crushing chamber and the length of the parallel belt. The standard type has a steeper moving cone inclination and a shorter parallel belt; the short head type has a gentler moving cone inclination and a longer parallel belt, and the intermediate type is between the two.